Seismic hazard is among the most important natural threats to atmospheric and storage tanks. A seismic event can cause events such as fire and explosion, resulting in a domino effect. Seismic loads are calculated using the seismic hazard curves of the region. The seismic hazard values of this region, the maximum location and spectral acceleration values for various return periods are calculated from the National Earthquake (TDY-2018) standards.

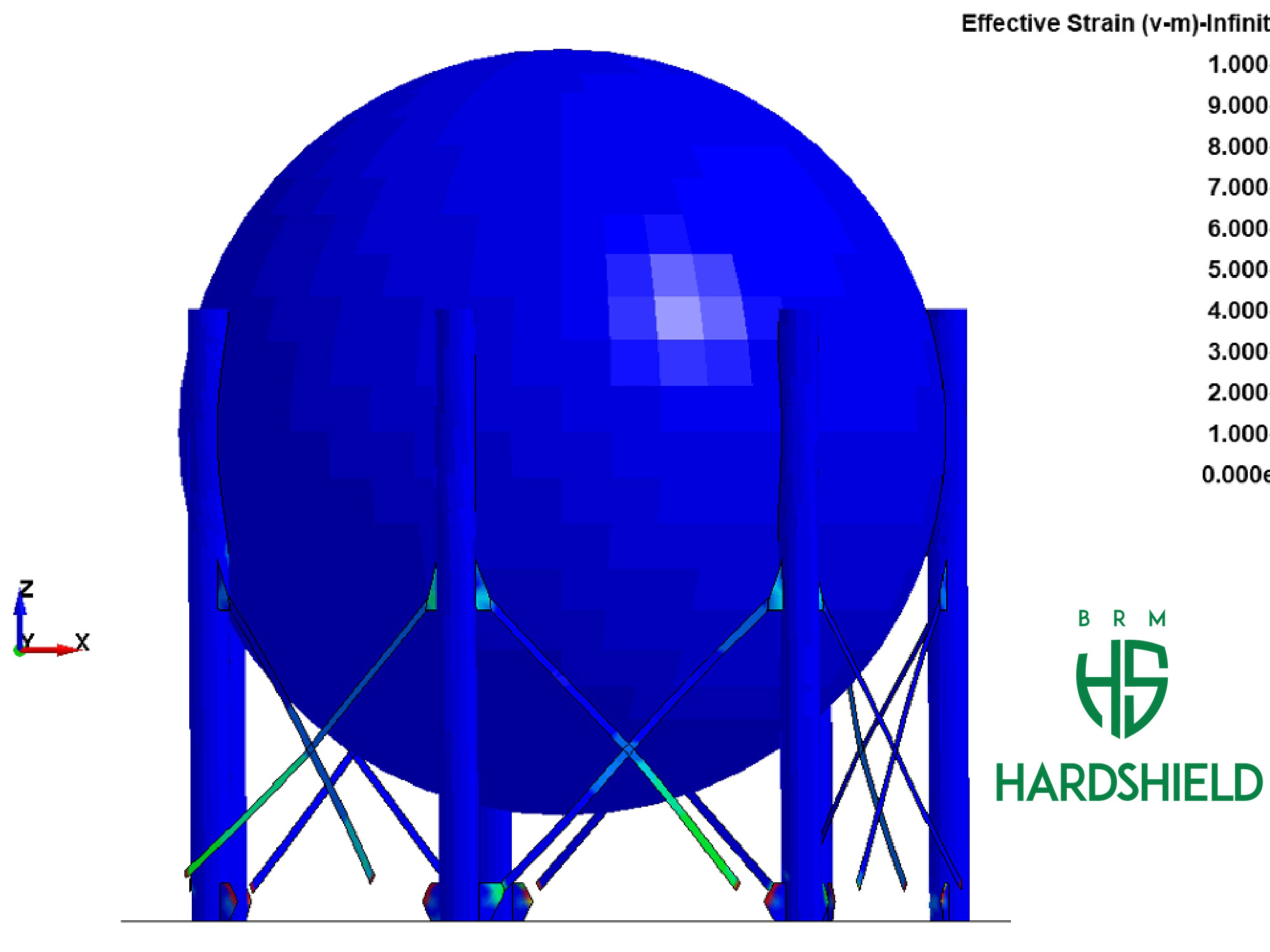

In order to determine the seismic behavior of storage and atmospheric tanks, the effects of bottom shear and sloshing on the overturning moment must be calculated. Pipe tank connections and storage tank should be inspected against earthquakes and should be considered as a possible leakage effect, ie domino (knock-on) effect, due to the damages that may be caused by the earthquake. Thus, all potential consequences of seismic activity must be taken into account. The most important potential earthquake damages for spherical tanks are listed below:

• Column sprain

• Damage to steel cross members

• Damage to pipelines

• Welding/bolting connections

• Corrosion

The fire and explosion accident in global storage tanks for Liquefied Petroleum Gas (LPG) in Chiba prefecture in Japan occurred due to the Great East Japan earthquake ground motion in 2011. Cross members made to support the columns of a spherical tank, which was then filled with water to evacuate air, were broken by the force of seismic inertia. Later, buckling of the columns by the aftershocks occurred. Fires and explosions triggered by seismic effects (domino effect) in spherical tanks continued for 10 days without interruption.

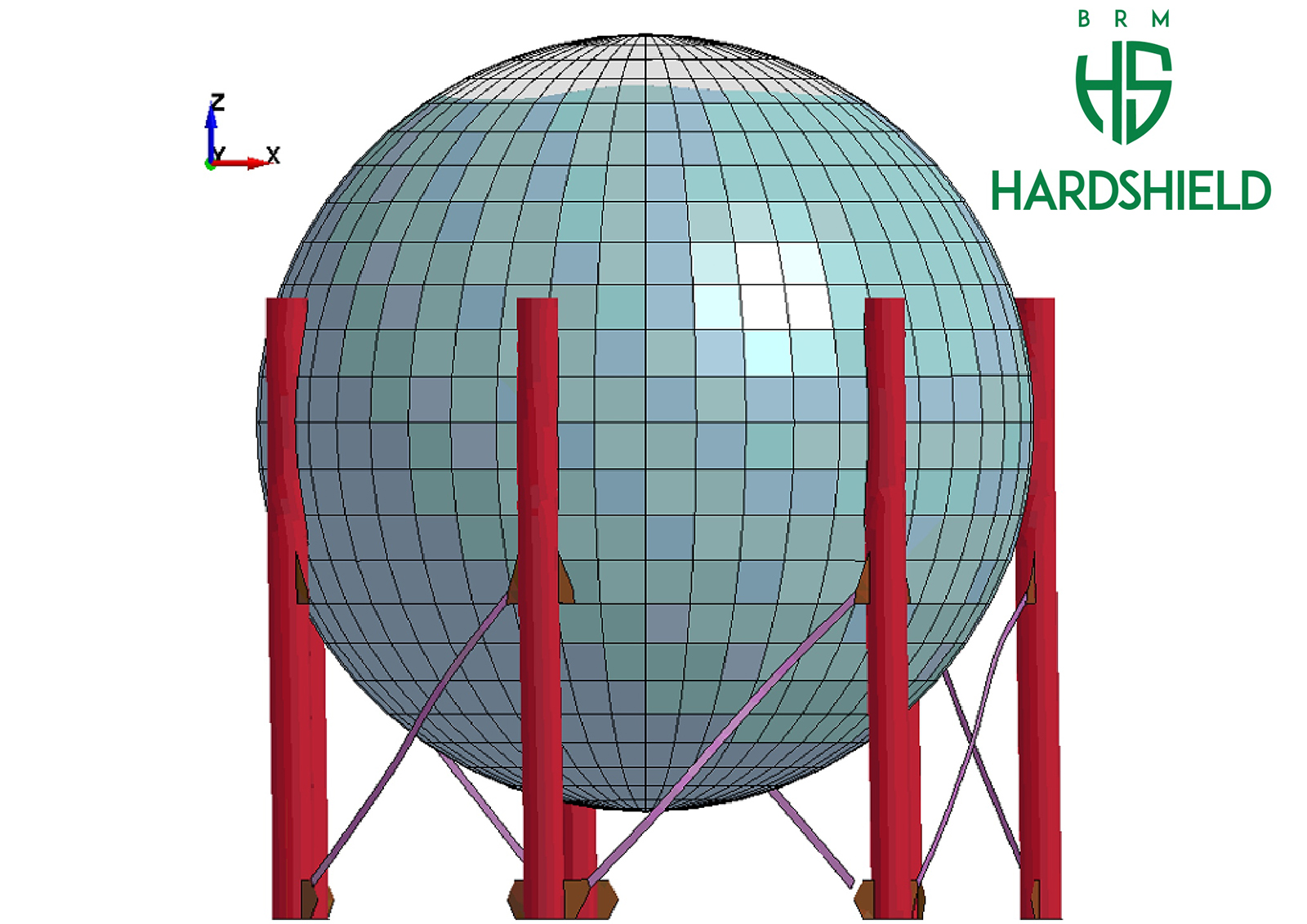

In seismic performance analysis, earthquake records are selected in accordance with the definition in the regulation, in accordance with TDY-2018, and a three-dimensional analysis (time-history analysis) is performed in the time history. In this context, the nonlinear behavior of three-dimensional spherical tanks containing liquid under earthquake loads is examined with LS-Dyna or Abaqus software using the finite element method (FEM), which can consider all nonlinear behavior sources of the tank-liquid interaction.

Contact us for more information.